IoT Brings Unlimited Business Opportunities & Advantages

In 2020, the worldwide market for IoT solutions will reach $7.2 trillion USD. 85% of existing industrial embedded devices are unconnected. As a result, business, the business opportunities for the IoT will be multiplied times 30 and there will be more than 50 billion sets of networked devices or components used in the world by that time.

Due to the Internet of Things (IoT) and Industry 4.0, billions of sensing devices have become connected and are used for distributing various kinds of information throughout the world. It can be utilized for environmental monitoring, petrochemical, electricity and renewable energy, transportation, health care systems and other industries. There is large potential for IoT in developing economies.

Applications for Factory Automation & Smart Energy Utilities

Axiomtek has continued to research and innovate and is working to actively integrate IoT applications software which contains a variety of easy-to-use management utilities and agent service. These service includesIntel® IoT Gateway Solution, Windows® 10 IoT and Axiomtek self-developed AXView 2.0 intelligent embedded monitoring software solutions for IoT application, featuring SNMP, MQTT, MODBUS, SNMP Trap, and email support for industrial secured IoT management. Furthermore, Axiomtek also develops a variety of protocols such as EtherCAT and fieldbus which can easily integrate with different controls, enterprise networks, and the cloud. It can also establish a smart factory automation system to help end-users achieve the goals of an Industry 4.0 compliant factory.

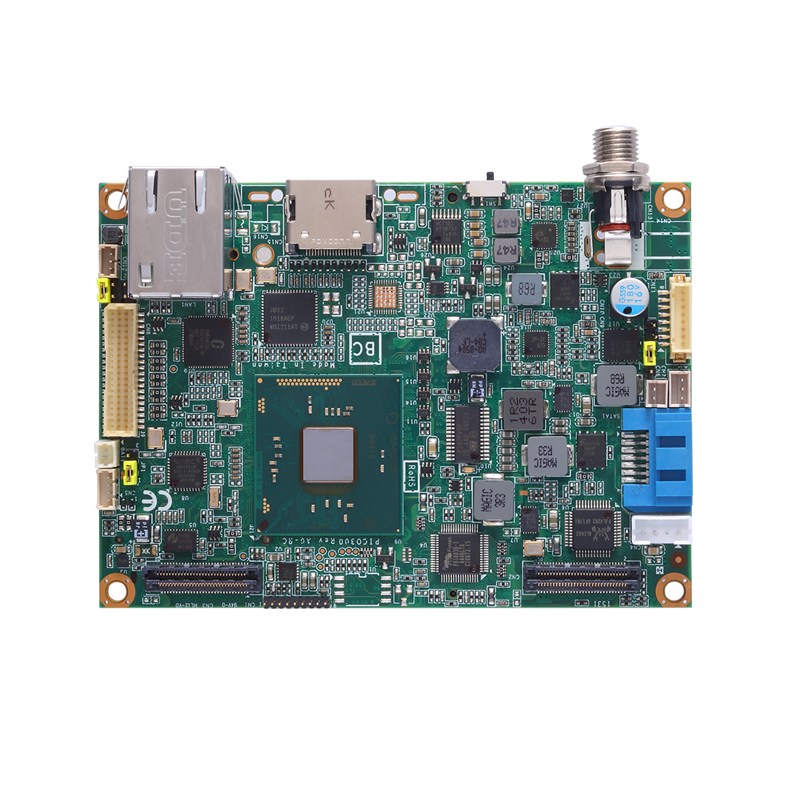

Rugged IoT Gateway Platform

Axiomtek’s rBOX & ICO products have the following features which offer intelligent IoT solutions for factory automation and smart energy utilities application:

Compact, robust, fanless and cable less design, wide voltage range of 12V – 48V DC-in with terminal block, and a wide operating temperature range of -40°C to +70°C. These features make the rBOX and ICO products well suited for harsh and space constricting environments, remote management, and IoT/M2M applications.

The ICO310-PD comes with Power over Ethernet (PoE) to make network equipment more flexible as well as simplifying factory automation as well as lowering costs for implementation, operations, maintenance and security protection mechanisms.

These systems meet many safety requirements to provide higher operational reliability and stability, such as heavy industrial CE, FCC Part 18, UL/cUL60950-1, IEC60068 and EN50121-4.

The rBOX510-6COM obtained the ATEX and C1D2 anti-explosive certifications for safe operation in hazardous environments, such as oil field developments, industrial plants, gas stations, chemical plants, oil factories, and paint factories.

Low Power Expandable Panel PC for Conveyor System Control

Intelligent AXView 2.0 is designed to meet the needs of applications for IoT/M2M , ranging from physical layer connectivity, communication layer protocols, middleware API, high level software for remote management, store Apps ,and the service cloud. So it is idealfor the application of factory automation and smart energy.

Employ agent of AXView 2.0 turns rBOX510 into smart IoT gateway platform which collects sensor/device/system data, stores and connects to the service cloud. With “Service Cloud” of AXView 2.0 installed, rBOX510 could be used as the service cloud platform.

For remote monitoring and management, among AXView 2.0 there is App which facilitates setting up remote monitoring/management system, saving time and cost for launching system to markets.

Factory Automation & Smart Energy