The New Era of Industry 4.0

In general, Industry 4.0 refers to a combination of digital technologies currently coming to maturity, including advanced robotics, artificial intelligence, sophisticated sensors, cloud computing, the Internet of Things, data acquisition and analytics, digital fabrication, and the embedding of all these elements in an interoperable global value chain, referred to as cyber-physical integration, on which all elements can now interact with one another using standard Internet-based protocols and analyze data to predict failures, configure themselves, and adapt to changes. Therefore, Industry 4.0 has created what has been called a “smart factory”, making it a reality to gather and analyze data across machines, thus enabling more flexible and more efficient processes to produce small volume goods of richer diversity and higher quality at a lower cost in a speedy fashion.

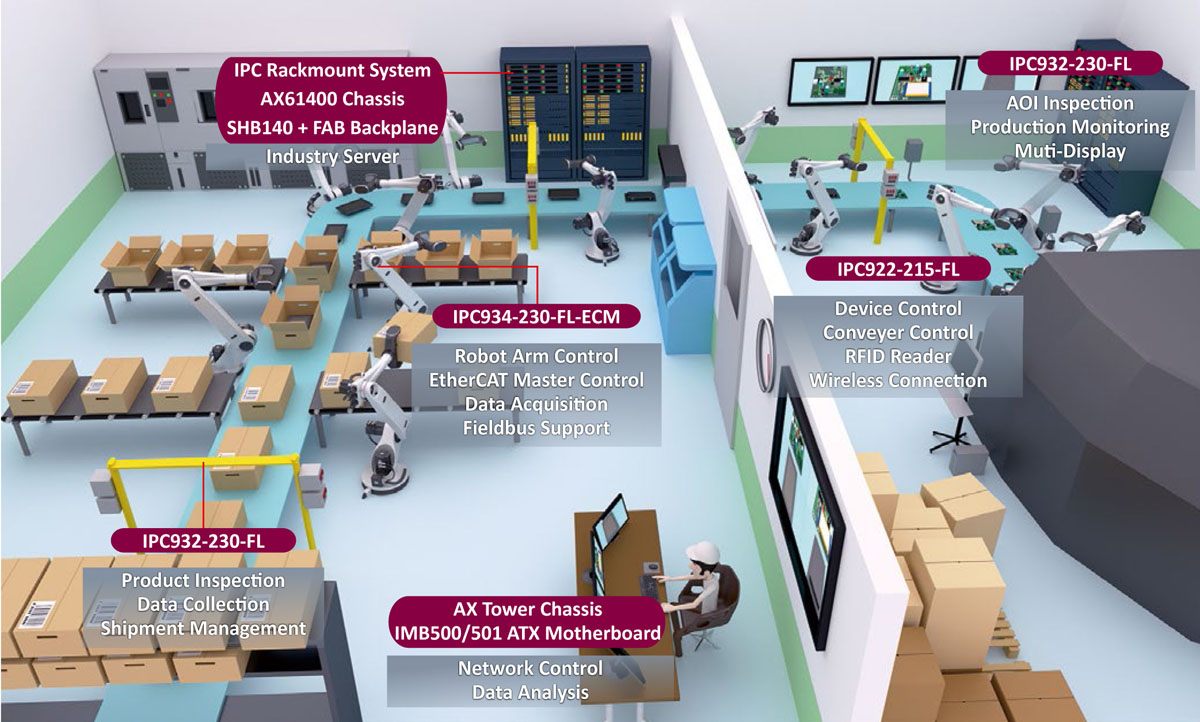

Axiomtek’s Smart Factory Solutions

On the one hand, Information Technology (IT) is utilizing data and information gathered through intelligent products and services, enabling manufacturers to better understand their customers whose experience in the age of Industry 4.0 is driven not only by physical objects, but also by data, information about the products and analysis on such data and information. On the other hand, Operating Technology (OT) is also helping improve the utilization of products, services and intelligent assets. For example, a company may incorporate smart monitoring sensors into its inhaler product lines for real-time data collection and analysis to improve manufacturing efficiency, maintain high quality and shorten lead-time of customization. Taking advantage of the cutting-edge IT and OT, Axiomtek’s reliable embedded solutions have made building smarter factory infrastructure unprecedentedly effortless.

The Competitiveness of Axiomtek plus KINGSTAR

Axiomtek, a leader in industrial PCs, has integrated its embedded systems with KINSTAR – a complete software platform for motion control, machine vision and programmable logic controllers (PLC) built on EtherCAT standards and supported by a 64-bit Windows real-time operating system (RTOS) – to give engineers leverage in designing, developing complex hard real-time systems, quickly and cost effectively, previously impossible with hardware, but now achievable in the Industry 4.0 environment. With superior PC processing power, faster motion control and machine vision networks, soft motion technology can potentially eliminate the use of hardware motion control and machine vision boards. Such an Axiomtek plus KINGSTAR solution can perform functionalities in stand-alone motions on machine vision controllers while splitting them among more capable drives and faster PCs, hence reducing programming costs, complexity and time, while improving programming maintenance, motion control and precision performance, overall delivering greater durability, reliability and data availability for factory automation.

Compatibility and Expendability

Overall, Axiomtek has offered a wide array of IPC series products, from entry-level to high-end, which fully support EtherCAT standards. Specifically, Axiomtek’s IPC932-230-FL-ECM, IPC922-215-FL, and IPC934-230-FL can support EtherCAT protocol at board level. Lastly, but not least, Axiomtek’s IPC solutions also support compatibility and expandability beyond board level through Fieldbus, expansion slots and IO cards. Furthermore, for system expansion, or to help reduce deployment and development time, specific motion or vision cards can be inserted into our various IPC series products along with an EtherCAT software bundle to facilitate product manufacturing and inspection, thus accommodating different user demands.